Click on the first image to start growing your Bluehouse Salmon

Transparen sea:

The Bluehouse Journey from Egg to Plate

Click on the first image to start growing your Bluehouse Salmon

Transparen sea:

The Bluehouse Journey from Egg to Plate

Our salmon eggs come from bio-secure, land-based farms in Iceland and Norway.

Bluehouse Salmon

spend the first 7 weeks of their lives in our hatchery. The eggs are incubated in a controlled environment

and then hatched into tiny alevin, fish that feed off their nutrient-rich yolk sac.

The hatchery

is designed to replicate the dark and sheltered conditions found in natural streams where salmon eggs and

young alevin develop.

The artificial gravel (substrate) in the incubator trays create hiding

places for the alevin, allowing them to remain undisturbed while they absorb their yolk material for body

development.

Once they’ve absorbed their yolk sac, the young salmon are called fry.

They can swim to the surface and begin to feed on their own. Our automated feeders deliver small, protein-rich pellets. Here the fish begin to school, swim actively, and grow rapidly until they reach the "parr" stage of their life cycle.

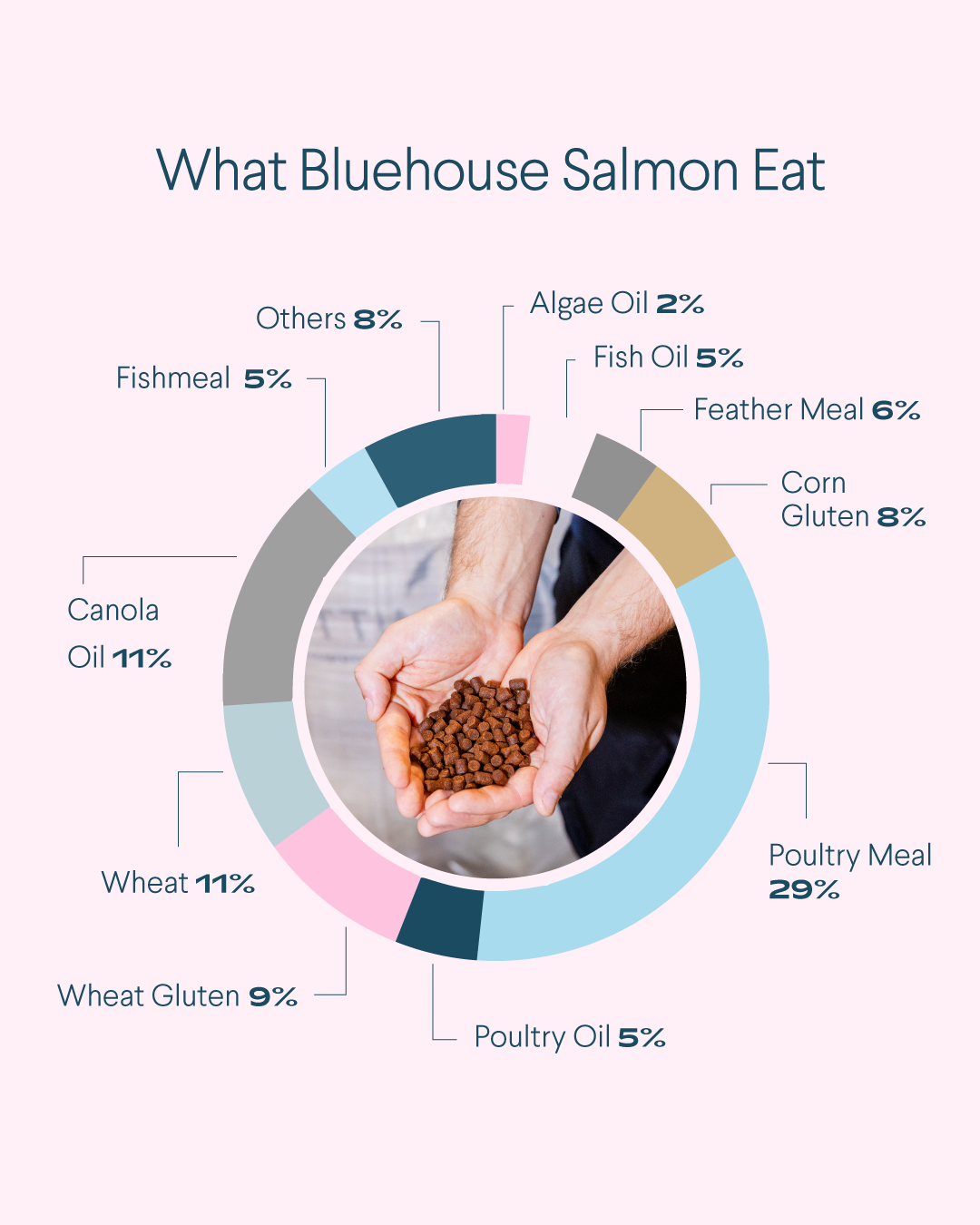

Our Feed

We’ve worked with our feed partner, Skretting, to develop a sustainable feed that meets the

nutritional needs of salmon without contributing to overfishing. Bluehouse Salmon enjoy a balanced diet

rich in protein, fat, carbohydrates, vitamins, minerals, and antioxidant carotenoids for color. All feed

ingredients are certified and meet or exceed U.S. and Canadian standards.

This approach

supports ocean health and has significantly reduced our reliance on marine ingredients.

Learn more about how we’re feeding the future with Bluehouse Salmon.

What do we feed Bluehouse Salmon?

Our young parr now undergo a physiological transformation known as smoltification, which allows them to survive in saltwater. Smolt typically grow until approximately 50 to 100 grams in freshwater before they are moved to larger saltwater tanks.

Our Bluehouse provides a controlled environment for smolt rearing, allowing for precise management of water chemistry, temperature, salinity, current and even lighting.

Clean, purified water is continuously cycled through our tanks every 30 minutes using advanced Recirculating Aquaculture System (RAS) technology.

Water Management

The Miami Bluehouse has an unique water source bringing a new level of purity to the product. The water is more than 20,000 years old and has never been exposed to man-made contamination such as microplastics.

Our water source is naturally purified through limestone rock in a sustainable ancient artesian aquifer.

Of all the water used, under only 5% is freshwater (from the Biscayne Aquifer) and over 95% is saline water (from the Floridan Aquifer), which is not otherwise suitable for agriculture or human consumption.

See our Sustainability Report to learn more.

Why raise salmon in Florida?

Bluehouse Salmon are gradually moved every 7 weeks. With each transition, the salinity of the water increases slowly and safely, replicating the shift from river to ocean life.

The number of fish in each tank is reduced with each fish transfer. As the fish grow in size the tanks will maintain an average density of 95% water and just 5% fish. Although salmon like to school together, we give them ample space to swim and grow.

By the time the salmon reach full maturity, they’re living in full-salinity saltwater sourced from the Floridan Aquifer, a natural saline water source.

Where does our water go?

We recycle and reuse 99% of the water we pull from the Floridan aquifer, using Recirculating Aquaculture Systems (RAS) technology. We like to call this Bluehouse-Tech.

What happens to the wastewater?

Less than 1% of this water is discharged as non-toxic wastewater through the injection well and into the Boulder Zone of the lower Floridan Aquifer, located at a depth of nearly 3,000 feet underground. This is the same wastewater disposal method used by Miami-Dade County.

The Boulder Zone acts as a storage zone with a natural current that slowly filters the water underground over thousands of years, until it returns to the ocean as clean water, eliminating any wastewater impact on the ecosystem.

See our Sustainability Report to learn more.

Where does the waste go?

Once our Bluehouse Salmon reach harvest size, they are processed on-site into consumer-ready products and loaded onto trucks for transportation to retailers, restaurants, and other customers. Each step is conducted under strict protocols that have helped us maintain a 100% compliance record with all food safety standards.

To reduce seafood waste and support a circular economy, we repurpose byproducts and food waste—selling them for use in aquariums, pet food, and other sustainable applications.

Because we harvest, process, and pack locally, our salmon go from tank to truck in just a few hours. The result: unmatched freshness and fewer transport emissions.

Once packed, our salmon is delivered fresh, not frozen, to retailers and restaurants across the U.S in 1-3 days.

Because we're based in the U.S., your salmon travels fewer miles, arrives fresher, and supports a more sustainable food system. Learn more about the benefits of eating local and find Bluehouse Salmon near you.

Why shop local

Energy Efficiency

In a major step toward our sustainability goals, we’ve partnered with Florida Power & Light to bring clean energy to our Bluehouse through their SolarTogether® program. This initiative now allows us to source 28% of our total energy consumption from renewable solar energy in the Sunshine State without the use of carbon offsetting. We look forward to increasing this percentage as more capacity becomes available through the continued growth of the SolarTogether® program.

Combined with our decision to never fly our fish, this marks a significant milestone in our mission to lower the carbon footprint of Bluehouse Salmon. It’s all part of our commitment to becoming the most efficient animal protein producer in the world.

See our Sustainability Report to learn more.

How do we power the Bluehouse?